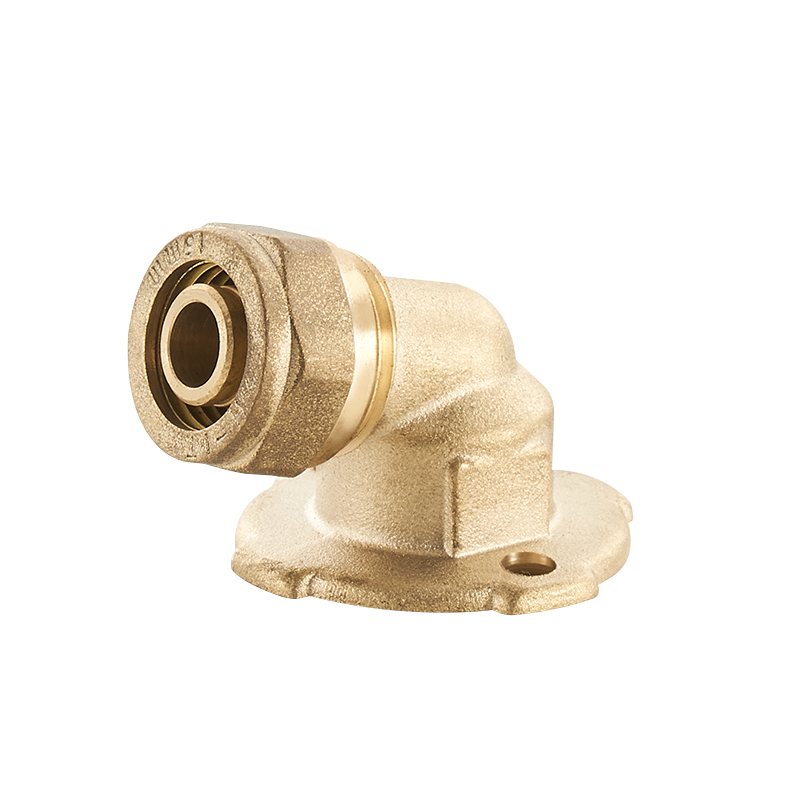

I-Equal Coupling Brass Compression Fitting For Pex Pipe

Ukucaciswa Ongakukhetha

Ulwazi Lomkhiqizo

| Igama lomkhiqizo | Ukulingana okuqondile okuhlanganisiwe kwe-Brass Pex Fittings | |

| Osayizi | 16, 18, 20, 22, 25, 32, | |

| Bore | Ibhore elijwayelekile | |

| Isicelo | Amanzi, uwoyela, igesi, nolunye uketshezi olungagqwali | |

| Ingcindezi yokusebenza | I-PN16 / 200Psi | |

| Izinga lokushisa lokusebenza | -20 kuya ku-120 ° C | |

| Ukusebenza ukuqina | 10,000 imijikelezo | |

| Izinga lekhwalithi | ISO9001 | |

| Qeda Ukuxhumana | I-BSP, NPT | |

| Izici: | Umzimba wethusi owakhiwe | |

| Ubukhulu obunembile | ||

| Osayizi abahlukahlukene abatholakalayo | ||

| Ukukhiqizwa kwe-OEM kuyamukeleka | ||

| Izinto zokwakha | Ingxenye eyisipele | Okubalulekile |

| Umzimba | Ithusi elibunjiwe, eliqhunyiswe ngesihlabathi | |

| Nut | Ithusi elibunjiwe, eliqhunyiswe ngesihlabathi | |

| Faka | Ithusi | |

| Isihlalo | Vula indandatho yethusi | |

| Isiqu | N/A | |

| Isikulufu | N/A | |

| Ukupakisha | Amabhokisi angaphakathi emakhathoni, alayishwe kuma-pallet | |

| Idizayini eyenziwe ngokwezifiso iyamukeleka | ||

Amagama Abalulekile

Ukufakwa Kwethusi, Ukufakwa Kwepayipi Lethusi, Ukufakwa Kwepayipi Lamanzi, Ukufakwa Kwethubhu, Ukufakwa Kwepayipi Lethusi, Ukufakwa Kwepayipi, Ukufakwa Kwepayipi Le-Pex, Ukufakwa Kwe-Pex, Ukufaka Ukucindezela, Okokufaka Kwepayipi Lethusi, Ukufakwa Kwethusi, Ukufakwa Kokucindezela Kwe-Brass, Ukufakwa Kwepayipi, Ukufakwa Kwe-Plumbi Ukufakwa Kwepayipi, Ukufakwa Kwe-Pex Push

Izinto Ongazikhetha

I-Brass CW617N, CW614N, HPb57-3, H59-1, C37700, DZR, Lead-free

Umbala Ongazikhethela Nobuso Kuqedwa

Umbala wethusi wemvelo noma i-nickel plated

Izinhlelo zokusebenza

Uhlelo lokulawula uketshezi lokwakha nokufaka amapayipi: Amanzi, uwoyela, iGesi, nolunye uketshezi olungagqwali.

Izinyathelo zokuqapha lapho okokufaka kokuminyanisa kwethusi kufakwa kuqala:

1. Uma ukufakwa kwamapayipi okucindezela ngethusi kufakwe ngaphambili, izindawo zokugcina zamapayipi kufanele zihlanjululwe.Ngemva kokuba ipayipi linqanyuliwe, kufanele lipholishwe esondweni lokugaya namanye amathuluzi, futhi ama-burrs kufanele akhishwe, ahlanzwe futhi aphephethwe ngomoya ocindezela kakhulu ngaphambi kokusetshenziswa.

2. Ngesikhathi sokufakwa ngaphambilini, i-coaxiality yepayipi kanye nomzimba ohlangene kufanele kugcinwe ngangokunokwenzeka.Uma ukuphambuka kwepayipi kukhulu kakhulu, uphawu luzohluleka.

3. Amandla okulayisha ngaphambilini akufanele abe makhulu kakhulu.Unqenqema lwangaphakathi lokucindezela kufanele lufakwe nje odongeni lwangaphandle lwepayipi, futhi akufanele kube khona ukuguqulwa okusobala ekucindezeleni.Uma ukwakheka kokuminyanisa kubi kakhulu ngesikhathi sokufakwa ngaphambilini, umphumela wokuvala uzolahleka.

4. Akuvunyelwe ukwengeza ama-fillers njenge-sealant.Ukuze kuzuzwe umphumela ongcono wokuvala, abanye abantu bafaka i-sealant kungcindezi yokubopha.Ngenxa yalokho, i-sealant iphonswa ohlelweni lwe-hydraulic, okubangela ukwehluleka njengokuvinjelwa kwe-orifice yezingxenye ze-hydraulic.

5. Uma uxhuma ipayipi, ipayipi kufanele ibe nesibonelelo esanele sokuguquguquka ukuze kugwenywe ukucindezeleka kwepayipi.

6. Uma uxhuma ipayipi, kufanele kugwenywe ukuthi kufakwe amandla ahlangene.Uma amandla asemaceleni emakhulu kakhulu, ukuvala angeke kuqine.

7. Lapho uxhuma ipayipi, kufanele liqiniswe ngesikhathi esisodwa ukuze kugwenywe ukuhlakazeka okuningi, ngaphandle kwalokho ukusebenza kokuvala kuzokonakala.

Xhumana nathi